No one asks us how we modelClick to apply

Nobody asks how we model - until it's too late.

Requests for quotations are usually about the perimeter, the number of storeys, sections, views and whether a 2D or 3D model is required. Some also ask about the desired level of detail. But one central question is almost always ignored: How will it actually be modeled?

It is precisely this question that will decide everything later on - especially if dimensions are not correct, planning comes to a standstill or the model is difficult to process. Many people today proceed according to a seemingly obvious principle: The point cloud is cleaned up, then loaded directly into CAD and breaklines are estimated visually.

What sounds logical is often riskily inaccurate in practice. In addition, the question arises as to whether your own computer can still work efficiently with the full amount of data.

This approach entails several risks. When cleaning up the point cloud, the very information that would be necessary for the clean detection of the actual break edges is often removed - especially in the case of deformed or complex old buildings. Anyone working directly in CAD rarely hits the exact break edge, but rather a random point somewhere in the vicinity. This is more of an estimate than precise work. And if the point cloud is shifted internally, these errors are transferred directly into the model unnoticed - with potentially serious consequences for the planning.

We do things differently.

Before we even open a CAD, we carry out a manual displacement analysis of the point cloud data. The reason for this is simple: the point cloud registration software currently available is not capable of reliably detecting such internal errors. It takes a scrutinizing eye - experience instead of automation.

In addition, we do not clean up our point clouds. What many workflows call cleaning up actually means deleting reality. For us, it is clear that every piece of information, however messy it may appear at first glance, has potential added value for modeling.

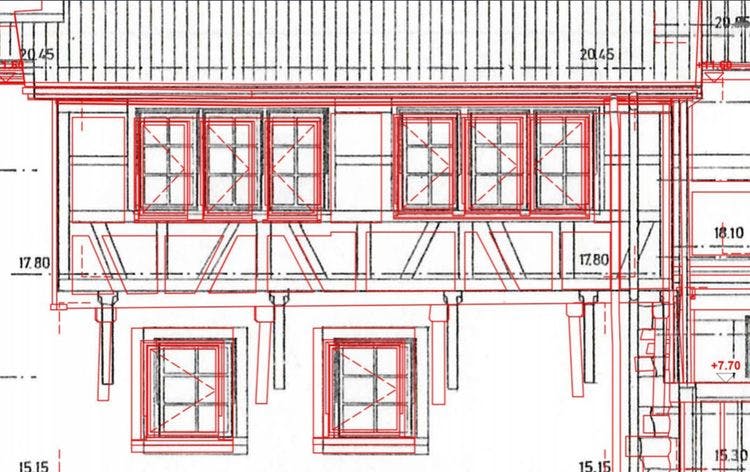

That's why the point cloud never ends up directly in CAD. We have developed our own tool with which we click point by point on the actual breaklines - not on noise, not on estimated lines, but on real geometries. Only these relevant, precisely tapped points are automatically transferred to the CAD system - in the software and in the format that our customers need.

Not the whole cloud. Only what counts.

Point by point.